When Johnson & Johnson needed to scale their Laboratory Analyst Training & Certification Program (LATCP) globally, they faced mounting challenges with traditional classroom-based training. Travel costs escalated. Training quality varied across locations. Most critically, laboratory analysts lacked opportunities to practice complex procedures without risking expensive equipment or hazardous chemical exposure.

This is a story about Johnson & Johnson partnering with Sify Digital Learning to deploy immersive virtual reality technology that enables analysts to build muscle memory and master standard operating procedures in a risk-free environment. It’s also a story about addressing rising laboratory human errors through innovative training methods that provide measurable, repeatable hands-on experience.

About Johnson & Johnson

Johnson & Johnson is a global pharmaceutical and medical device company committed to delivering breakthrough innovations in healthcare. With operations spanning multiple continents, J&J maintains rigorous standards for laboratory practices and Good Manufacturing Practices (GMP) compliance across all facilities. The company’s Chemistry Lab Analysts — who hold bachelor’s degrees in Chemistry with pharmaceutical laboratory experience — must complete extensive training to ensure they possess the knowledge, skills, and abilities to perform analytical tasks that support product quality and patient safety.

The Training Challenge

Before implementing VR technology, Johnson & Johnson operated a traditional classroom and laboratory-based LATCP program that required analysts to travel to designated training facilities. While this approach had served the company well initially, several critical challenges emerged as the organization scaled:

- Travel requirements created logistical barriers and substantial recurring costs as analysts traveled to training laboratories globally

- Training quality inconsistencies developed as different instructors delivered sessions across various locations, with no mechanism to guarantee equivalent instruction quality

- Assessment limitations emerged as instructors could only evaluate analyst performance through manual observation, which restricted visibility into actual skill mastery

- Limited practice opportunities meant analysts couldn’t repeatedly perform procedures without consuming expensive chemicals and lab consumables or risking equipment damage

- Human error rates had increased steadily over eight years, partly attributed to the erosion of the traditional three-prong training approach (observe, practice with expired samples, execute with supervision) due to resource constraints and pressure to onboard analysts faster

“The demand on resources to get product tested and to on-board new hires quicker have left the new hires inadequately trained, leading to lack of confidence, resulting in increasing the opportunities for human errors.”

Manager, Laboratory/Microbiology Analyst Training & Certification Program, Johnson & Johnson

Learning and Business Objectives

With clear understanding of these challenges, Johnson & Johnson and Sify Digital Learning outlined four key objectives for the VR training solution:

1) Make the LATCP program accessible virtually and globally within J&J to train analysts on basic analytical techniques using a virtual laboratory system

2) Equip laboratory analysts with conceptual knowledge and skills before they perform actual analytical chemistry experiments in the lab

3) Automate the assessment of analysts on actual lab skills and identify knowledge and skill gaps

4) Evaluate analysts based on metric-driven task performance defined via a skillometer—a custom skill-measuring gauge

The Haptic Glove-Based VR Solution

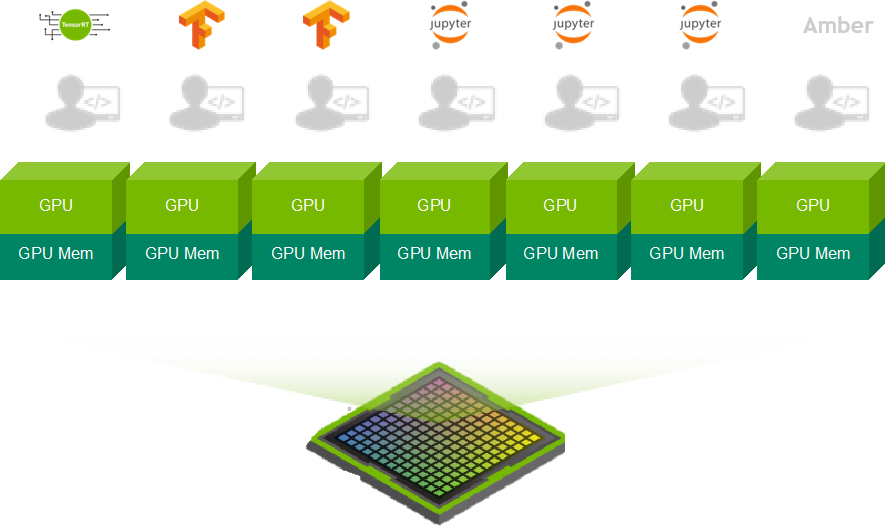

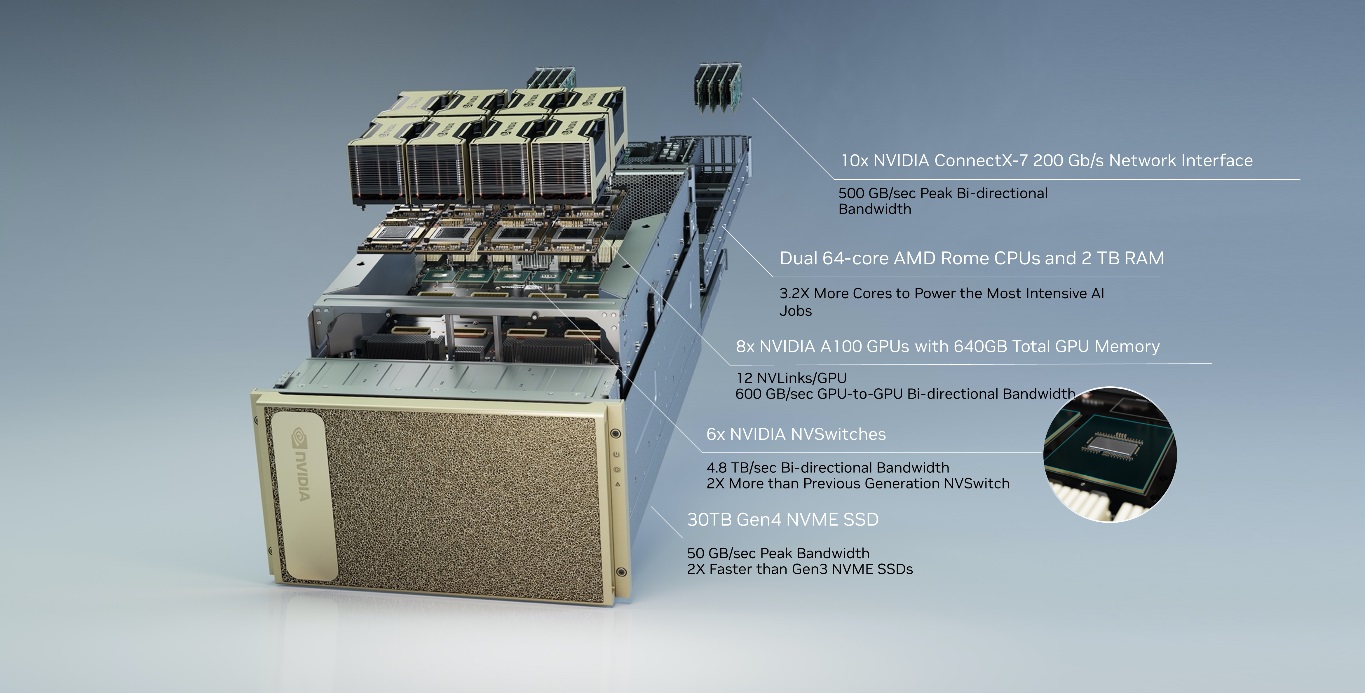

Sify Digital Learning developed a breakthrough approach that addressed previous limitations of VR training applications. Earlier VR labs relied on game-based controllers that failed to mimic natural hand and finger movements, creating experiences that didn’t adequately prepare analysts for real laboratory work.

Sify’s solution integrated haptic glove technology that enables natural, real-world actions in the VR environment. Analysts can drag, pick, pour, swirl, pull, push, grasp, hold, and tap virtual objects—replicating the precise procedural skills required in actual laboratories. The haptic gloves provide vibration feedback during these interactions, which helps build muscle memory essential for performing laboratory procedures correctly.

The pilot implementation focused on creating a VR High-Performance Liquid Chromatography (HPLC) Analytical Lab that mirrors Johnson & Johnson’s actual HPLC facilities. The system enables analysts to perform and practice lab exercises for preparing Buffered Mobile Phase Solutions—a fundamental skill required to run HPLC systems.

Key Features and Innovations

The HPLC VR Lab incorporates several distinctive design elements:

Two Training Modes:

“Guide Me” mode provides ghost-hands-based guidance that walks users through each step of standard operating procedures in compliance with Good Laboratory Practices. Instructional scaffolding includes text, graphical hints, tips, critical notes, visual feedback, and conceptual animations.

“Try It” mode offers a fully simulated VR lab environment without guidance, allowing analysts to practice independently while receiving feedback when they deviate from SOPs. This mode tracks skill development through the custom skillometer.

Realistic Laboratory Environment:

The VR lab replicates components from Johnson & Johnson’s actual laboratories, including worktables, appropriate lighting, glassware, consumables, and equipment such as weighing machines, pH meters, and HPLC systems. This familiarity helps analysts build positive associations during the learning process.

Skillometer Dashboard:

This unique tracking system monitors critical skills across two levels: Skills and Skillets. As analysts demonstrate competency through correct responses, progress bars change from yellow (not yet achieved) to orange (in progress) to green (completed). Red indicates skills that required more than five attempts, highlighting areas needing additional practice. The dashboard enables instructors to evaluate analyst performance electronically and guide their progress.

Quick Access Tools:

A heads-up display (HUD) presents progress information visually and allows intuitive teleportation between different lab modules through finger gestures. Quick Access Toolbars provide gesture guides, user positioning information, and access to the skillometer — all designed to minimize the learning curve for the VR system itself.

Modular Lab Exercises:

The pilot program included five experiments analysts must complete:

- Prepare 1 M Phosphoric Acid

- Prepare 10 mM Phosphoric Acid

- Prepare 1 M Potassium Phosphate, Dibasic

- Adjust pH of Buffer Solutions (including calibration and two pH variations)

- Prepare Mobile Phases with Acetonitrile and Methanol (four different ratios)

Measurable Outcomes

The haptic glove-based VR solution delivered several quantifiable benefits:

Scalable Hands-On Lab Experience:

While traditional lab demonstrations incur recurring costs — travel, facilitation, chemicals, lab consumables — with each session, the VR lab provides unlimited hands-on, immersive experiences with no additional cost. Analysts can repeat exercises as often as needed to achieve mastery.

Risk-Free Learning Environment:

Analysts practice and learn from mistakes virtually rather than in settings where errors could damage expensive equipment, waste costly chemicals, or create safety hazards. This freedom to make and correct mistakes allows analysts to examine procedures from different perspectives, identify execution flaws, and challenge assumptions.

Consistent, Measurable Assessment:

The VR system tracks, scores, and records all user interactions during experiments. Instructors can evaluate analysts electronically through the skillometer dashboard, providing objective, consistent assessment that manual observation cannot match.

Instructor Independence:

Analysts can participate in the learning process independently, without requiring excessive one-on-one instructor interaction — addressing the resource constraints that had eroded the traditional three-prong training approach.

Skill Reinforcement Tool:

The dual-mode design (Guide Me for knowledge acquisition, Try It for skill application) creates a structured path to mastery that aligns with evidence showing haptics and VR technologies improve long-term retention and build muscle memory.

What’s Next

“The VR module prototype is currently in a pilot state and we are gathering information from the business. We are excited to bring this innovative approach to help transform and holistically change the training approach for our analytical chemists and microbiologists at J&J.”

Manager, Laboratory/Microbiology Analyst Training & Certification Program, Johnson & Johnson

Looking ahead, Sify Digital Learning continues refining the VR training platform based on pilot program feedback. The success of the HPLC mobile phase preparation module positions the technology for expansion to additional laboratory procedures and analytical techniques. As Johnson & Johnson evaluates the pilot results, the company anticipates deploying haptic glove-based VR training across its global laboratory network, creating consistent, measurable, and scalable training experiences that maintain the rigor of hands-on laboratory instruction while addressing the practical constraints of traditional training approaches.

“This breakthrough addresses the core challenge we faced: providing new hires adequate opportunities to develop confidence and competence before working with actual product samples. By recreating nearly identical laboratory environments where analysts can practice procedures repeatedly without consequences, we’re investing in the foundation that reduces human errors and strengthens our quality systems.”

- Johnson & Johnson Training Leadership