“The AR application advanced and significantly improved ‘time to competence’ and confidence of trainee in a safe environment.”- Barbara Ann, Learning Partner & Specialist, Merck Manufacturing Division

How Merck Used AR-Based Performance Support to Cut Training Time and Accelerate Operator Competency

When pharmaceutical leaflet reels break, jam, or empty at high-speed packaging lines, operations must stop. Every minute of downtime means product doses don’t reach patients on time. Operators need to restart these lines quickly, but the splicing process is infrequent and complex. New hires and less experienced operators required extensive training—training that itself required stopping the production line.

This is a story about Merck Manufacturing Division partnering with Sify to replace traditional training methods with augmented reality technology. It’s about cutting training time by more than half while producing 371,250 additional product packs per week.

About Merck Manufacturing Division

Merck is a global healthcare company that discovers, develops, and provides innovative products and services to improve health worldwide. The Merck Manufacturing Division operates pharmaceutical production facilities that serve patients globally. At these high-speed packaging lines, operators handle critical processes where time, accuracy, and compliance with Good Manufacturing Practices are essential to getting medicine to patients safely and efficiently.

The Challenge: Traditional Training Methods Couldn’t Keep Pace

Before implementing the AR solution, Merck Manufacturing Division trained operators on the GUK machine’s splicing process using in-person instruction at the job site, supported by written instructions and videos. This traditional approach created several operational challenges:

- Training required shutting down the packaging line, which delayed production and affected cycle times

- Training was postponed until scheduled shutdowns, resulting in fewer qualified operators who could execute splicing tasks

- Experienced operators had to be pulled from other lines to perform splicing, disrupting workflows across multiple production areas

- New operators took 12 minutes to complete a reel change after training, compared to 5 minutes for experienced operators—a 7-minute difference that cost hundreds of product vials per incident

- The splicing process occurred infrequently, giving operators limited opportunities to retain skills and maintain proficiency

- Testing and qualifying operators on SOPs required additional line stoppages

Barbara Ann, Learning Partner & Specialist at Merck Manufacturing Division, explains the scope of the problem: “The previous hands-on method had a training timeline of over a year for an employee to be able to do this change out in the required 5 minutes. The 7 minutes difference meant that hundreds of vials of product that would have been packaged in that time would not make it to our clients without costly overtime.”

The Business Objectives

Merck Manufacturing Division and Sify outlined four clear objectives for the AR-based training and performance support solution:

- Provide operators essential knowledge of the splicing process and enable real-time performance support to execute tasks at the job site

- Reduce the time required for new or inexperienced operators to complete reel changes from 12 minutes to 10 minutes

- Reduce equipment downtime and produce 148,500 additional packs per week

- Train operators more effectively to ensure faster product supply to customers

The Solution: A 3-in-1 AR Application

Merck and Sify selected augmented reality technology over traditional performance support tools because AR allows operators to visualize and interact with the machine in three dimensions. The iPad-based application serves three distinct functions: training, qualification, and on-the-job performance support.

Training Mode: Virtual Shop Floor Experience

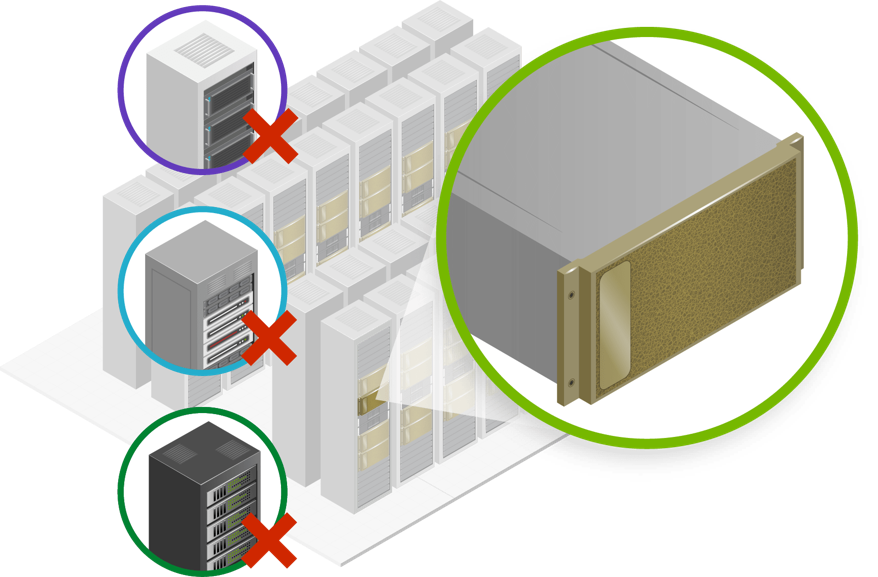

The AR app uses Apple’s ARKit to place a full-scale 3D virtual GUK machine on any flat surface — a table, floor, or available room space. Operators interact with this virtual machine without needing access to the physical equipment or stopping the production line.

The training module includes two distinct learning paths:

Teach Mode provides step-by-step guidance using spatial form highlighters, instructional text, graphical hints, tips, critical notes, visual feedback, conceptual animations, and short videos (each under 40 seconds). Operators learn to complete each task in compliance with established Good Manufacturing Practices.

Try Mode removes all guidance and instructional scaffolds. Operators complete tasks on the simulated machine while a custom skill tracker monitors their performance. The system provides feedback when operators deviate from SOPs, allowing them to correct mistakes and build proficiency safely. User interactions include tapping, dragging, and swiping 3D objects. Operators physically move around the virtual machine, bending to reach lower components and raising up for eye-level parts—mirroring the real-world experience.

A skill tracker categorizes operator proficiency as Beginner (red), Intermediate (yellow), or Expert (green) based on correct actions and completion attempts.

Performance Support Mode: Real-Time Job Aid

At the packaging line, operators launch the app, scan a QR code on the physical GUK machine for calibration, then point the iPad at specific components. The app overlays contextual SOP information directly onto the physical machine as spatial highlights, arrows, and text or audio instructions. Operators access any task details in any order, receiving step-by-step guidance without interrupting workflow or constraining productivity.

What Makes This Solution Different

iPad Accessibility Over High-Cost Hardware

While hands-free AR devices like HoloLens offer immersive experiences, they require significant investment. The iPad-based approach makes the solution scalable and accessible across multiple manufacturing sites without specialized hardware setup.

Immersive Learning for Long-Term Retention

The first-person AR experience allows operators to learn by doing, merging virtual and physical worlds. Operators practice at their own pace without requiring expert or coach support, decreasing instruction time and enhancing the learning curve through unlimited practice.

Safe Environment for Mistakes

The virtual environment recreates the real-world GUK machine and its functions with precision. Operators make mistakes and learn from them without costly real-world consequences. This freedom to fail safely allows operators to examine tasks from different perspectives, identify execution flaws, and challenge assumptions.

Built-In Qualification Metrics

The skill tracker captures critical knowledge and skill gaps through user interactions during Try Mode. Managers receive quantifiable data on operator readiness, standardizing qualification processes across all employees.

The Results: Beyond Expectations

Barbara Ann describes the impact: “Using the AR training changed this during the piloting of the tool. Within an afternoon, trainees who completed the AR training could change the reel at a speed comparable to an experienced operator. The training technique was embraced by the trainees and coaches alike. Management embraced the tool as it standardized the time across all employees regarding the reel change and machine down time enhancing predictable supply.”

The measurable benefits exceeded the initial objectives:

- Reduced reel change time from 12 minutes to an average of 5 minutes — matching experienced operator performance and exceeding the 10-minute target

- Increased weekly production by 371,250 packs — 2.5 times the expected 148,500 additional packs

- Reduced operator learning time by 58%, significantly improving time to competence

- Saved 1,485 minutes of equipment downtime per week

- Enabled faster product supply to customers by training operators more effectively

What’s Next

“There was also a positive response for the training method used in the application,” says Barbara Ann. The success at the initial site has positioned the AR-based training and performance support tool for expansion across the Merck Manufacturing Division network.

The scalable, iPad-based design allows deployment at additional facilities facing similar challenges with infrequent tasks, complex procedures, and the need to maintain production while building operator competency. Merck can now train operators effectively without costly production interruptions—ensuring medicine reaches patients faster while maintaining the highest quality and safety standards.

Arun Venkatachalam, Senior Vice President, Digital Learning, Sify Technologies: “This AR solution demonstrates how immersive technology can solve real manufacturing challenges. By combining training and performance support in a single application, we’ve helped Merck transform operator readiness while protecting production uptime. The results speak to the power of designing technology around actual workflow needs.”